Circular Vibrating Screen

Metaflow offers wide range of sizes (450 mm to 2400 mm) in their Circular Gyratory Screen line-up.

Circular Gyratory Screens, with their modular design, are first choice in most industries when standard grading/scalping/size separation operations are to be performed.

With latest designs, operation friendly features and superior quality manufacture, Metaflow Circular Gyratory Screens offer the most reliable source for a screening application –backed by efficient service team.

Purpose

Segregation of dry bulk solids into desired size fractions (upto five size fractions simultaneously in one machine) . Metaflow Circular Gyratory Screens may also be used for solid-liquid separation. These screens are used also for scalping and fines removal. Inline screen is a short height screen that removes coarse impurities and gives product output for next operation stage.

Principle of Operation

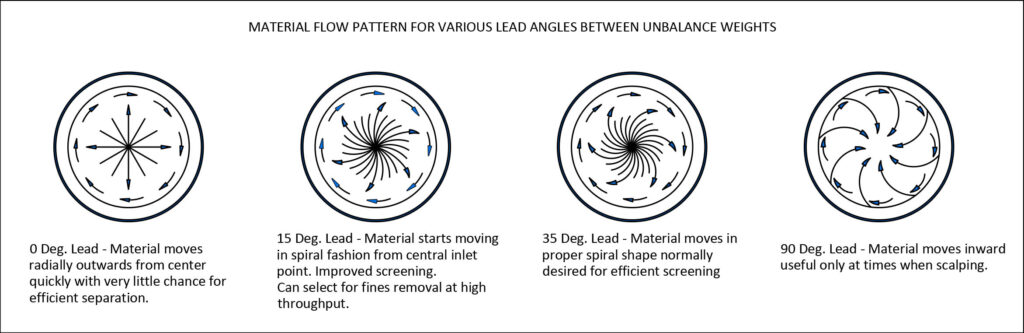

In Circular Gyratory Screens, the shaft of the unbalance weight vibrator is aligned with the machine axis. The position of the unbalance weight vibro motor in Y axis governs vibration pattern. Generally the upper unbalance weight, being closer to the center of gravity, imparts vibrations in more or less horizontal plane while the lower unbalance weight provides vibrations in vertical plane. The material thereby gets spiral hopping trajectory on screen effecting separation and flow from centre to the outlet spout. The adjustment of unbalance weights is important for proper setting of machine for required purpose . Followiing figure describes various material flow patterns on screen for the corresponding unbalance weight settings:

Features

- Material of construction CS, SS-304, SS-316L and any other special steel/non-ferrous as per job requirement

- Quick opening clamps for quick screen frame replacement / cleaning / maintenance

- Easy arrangement for unbalance force adjustment

- Wheel mounted machines for easy mobility (smaller models)

- Anti-blinding balls/rings/both as per job requirement

- Taut mesh for efficient screening

- Modular design for addition/deletion of any screening frame for changed plant requirement