Bin Activator

Purpose

- Facilitate easy, predictable and on-demand take off of dry bulk materials out of storage silos / bins. Bin Activators are proven silo discharge aids and thereby providing reliable plant performance and reduced headaches to plant operation and maintenance teams.

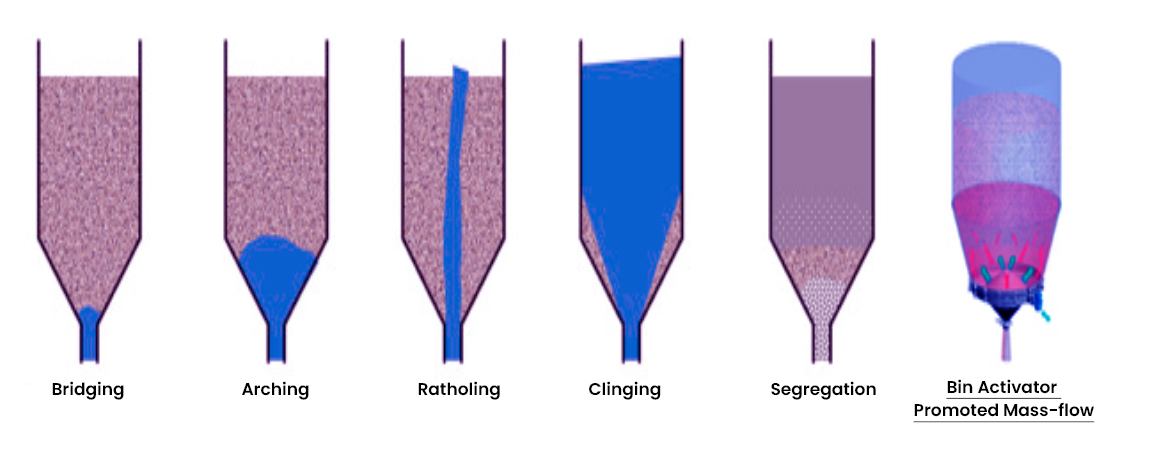

- While facilitating on-demand material flow for even the most difficult-to-flow materials, Bin Activators, due to their principle of operation, promote mass flow thereby reduce segregation, rat holing , arching and caking. This helps in preserving a more homogenous inventory in the storage silo/bin.

Principle of Operation

In essence, Bin Activator provides a live bottom to a bin or silo at about the most likely arching cross section. The gyrating inverted cone of the bin activator at most likely arching diameter continuously imparts shear force onto the column of material above it thereby breaking the arching and assisting free flow out of the bin.

In addition, the surface of the cone transmits forces into stored media right upto vertical walls. This gyrating force induces gentle churn into the stored material and reduces segregation and rat hole.

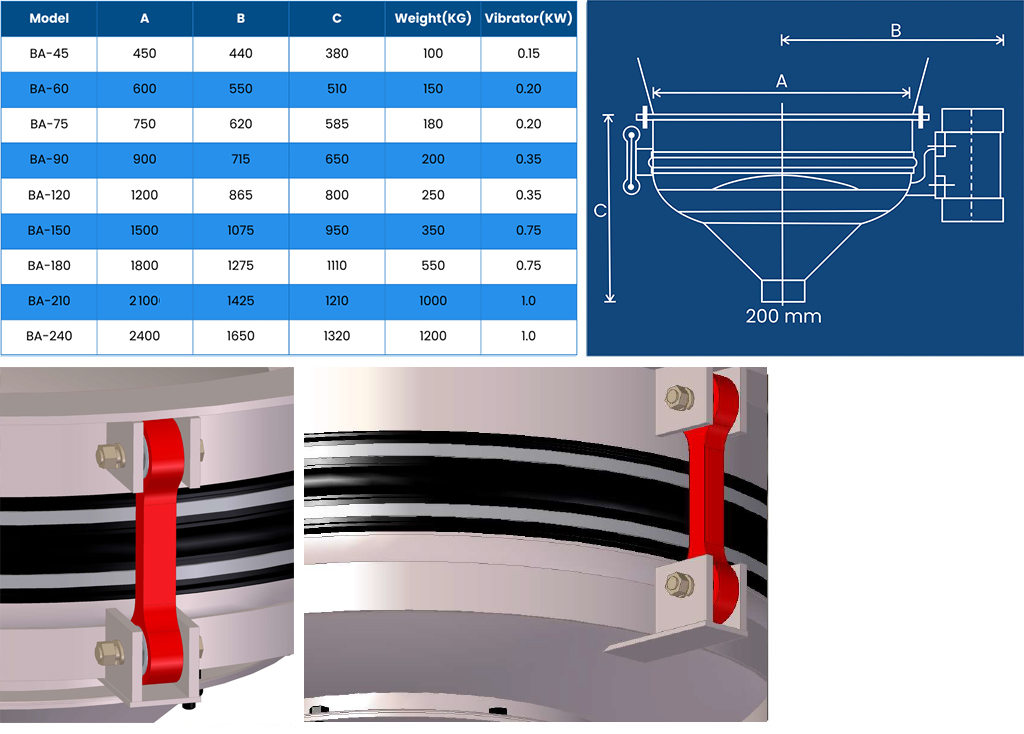

Careful selection of inverted cone profile, the sizing of bin activator and selection of vibrator –all depend on the material properties like bulk density, friction angle, repose angle, cohesiveness properties etc.

Features

-

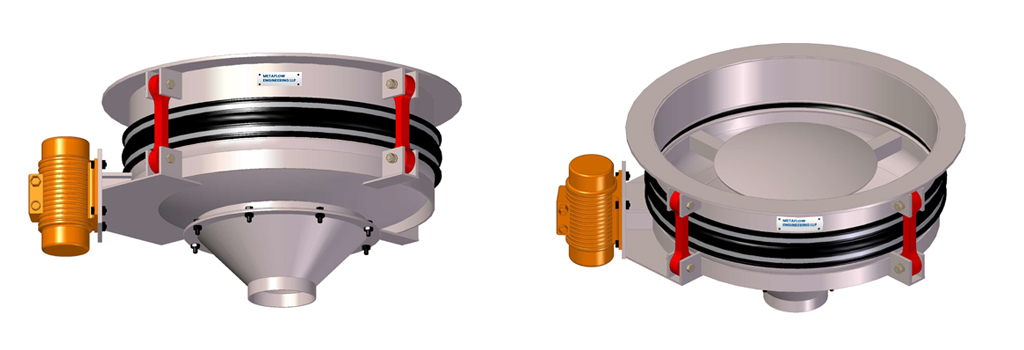

Metaflow Bin Activator range covers very small hoppers to large silos.

-

Metaflow selected vibrators are sturdy induction motors having IP55 enclosure. The frequencies range from 750 to 3000 rpm selected depending upon the job at hand.

-

Throughput may be adjusted to some extent by varying vibration amplitude that is accomplished in machine stationary condition by adjusting unbalance rotating weights. There is also provision for adjusting the inverted cone height in a disassembled stationary unit to overcome inadequate flow properties.

-

Material of construction for contact with bulk material can be selected as per requirement dictated by corrosion properties as well as hygiene requirements in food & pharma industries. SS-304, SS304L, SS-316, SS316L are normally provided for above mentioned cases. Carbon steel St37-2 is standard material for non-special duties.

-

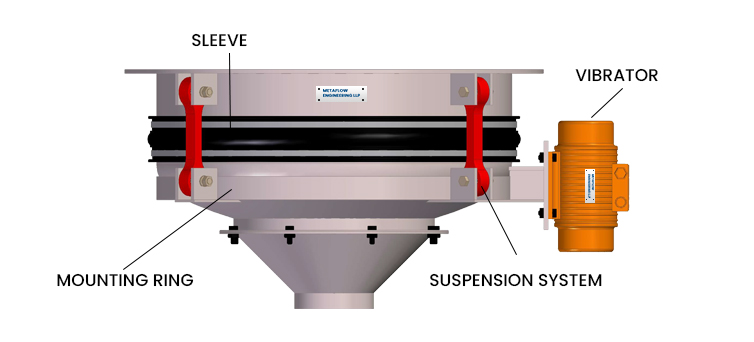

Vibration isolators are high strength rubberised steel hangers. These specially designed hangers are sturdy enough for taking vertical static and dynamic loads and at the same time effective in vibration isolation.

-

Endless neoprene sleeve with nylon reinforcement and effective fitment by way of retaining rings and strong high tensile clamps ensure no powder leaks when Bin Activator is at work.

Dimensions in mm

Note: The company reserves the right to change / modify the product design & specifications for further improvements without prior notice.